The biggest manufacturer of World Class Collets.

The biggest manufacturer of World Class Collets.

Send us your enquiry with collet drawings, we will quote and supply your requirements as per your drawing, keeping runout and various other dimensions at precision.

Send your drawings to infotoolsengg@gmail.com - We have dealt with 1000s of special varieties of collets over the years so we are very famaliar with your requirements for collets, feel free to contact us at anytime. We are always here to help.

Workholding collets (Outside diameter holding type)

Stationary type collets

| ・ | Stationary type collets are used for processing which wants to decide the axial direction of a workpiece correctly. |

| ・ | There is no dispersal in the axial direction because the collet itself does not move. Therefore, it is used by the secondary processing which wants to decide the axial direction correctly. | |

| ・ | Stationary type collets can be used as tool holding collets with using the nose cap. |

|  | |

|  | |

|

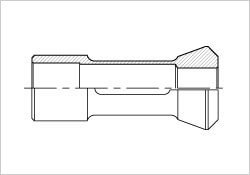

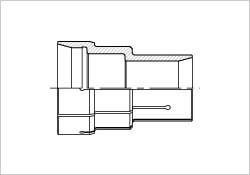

Draw back type collets

| ・ | Draw back type collets draw the collet itself and hold a workpiece using the screw of back portion. These collets are used for primary processing, such as NC lathe, in many cases. |

| ・ | Draw back type collets can be expected high precision compared with stationary type collets. Moreover, rigidity is high. | |

| ・ | Positioning of the axial direction is not stabilized as compared with stationary type collets. |

|  | |

|  |

| ・ | Push type collets push the collet itself on the nose cap, and hold a workpiece. Therefore, the workpiece moves in the axial direction when it is held. |

| ・ | High precision is not expectable since it is hard to take out concentricity with taper of the nose cap. However, it is effective to avoid interference with cutting tools. |

|  | |

|  | |

|

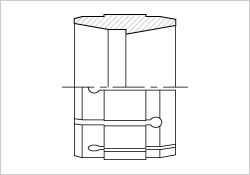

Tan line collets

| ・ | Tan line collets are mainly used for hobbing machine, such as Gleason (U.S. manufacture), and is indispensable to processing of differential gear of cars. |

| ・ | These collets have the structure of clamping each part by two tapers and are suitable for clamping long workpiece. |

|

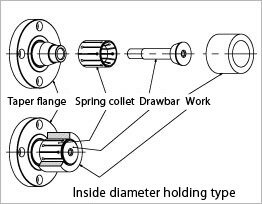

Workholding collets (Inside diameter holding type)

Double taper expansion collets

| ・ | Double taper expansion collets are standard form as expansion collets for inside diameter clamping type. It is made to be expanded by drawing the central part of the collet with a drawbar, and clamp a workpiece. |

| ・ | These collets open in parallel since there are flexing slots from both sides of front and back. | |

| ・ | According to the form of these collets, a little more clamping range in a free state can be taken. |

|  | |

|  | |

|

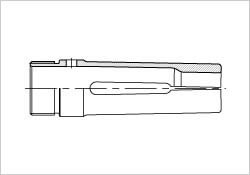

Single taper expansion collets

| ・ | Single taper expansion collets are used for primary processing, such as NC lathe, in many cases. |

| ・ | It is made to be expanded by drawing the central part of the collet with drawbar, and clamp a workpiece. | |

| ・ | These collets open in parallel since there are flexing slots from both sides of front and back. | |

| ・ | High precision is expectable as compared with double taper expansion collets. |

|  | |

|  |

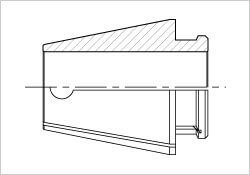

Flange type expansion collets

| ・ | These are expansion collets with flange. It is made to be expanded by drawing the central part of the collet with a drawbar, and clamp a workpiece. |

| ・ | These collets may not open in parallel in case of the specification that the bore of the collet is opened widely in a free state since one side of the collet is a flange. | |

| ・ | It’s easy to insert a workpiece since more clamping range in a free state can be taken. |

|  | |

|  |

Expansion disk

| ・ | Expansion disk is used for the gear cutting machine along with the tan line collets, and is indispensable to processing of differential gear of cars. |

| ・ | Expansion disk has the structure faces two plates together face to face and makes an outside diameter extend by compressing, and clamp a workpiece. | |

|

Carriage collet chucks

Feed fingers

| ・ | Feed fingers are used as collets for supplying a workpiece of NC lathe and multi spindle lathe with auto bar feeder. |

| ・ | These are called “pusher” since these are collets which push in bar material. |

|  | |

|

Finger collets

| ・ | Feed collets hold a workpiece only by the spring force of the collet itself. Therefore, cautions are needed for clamping heavy workpiece. |

| ・ | The whole equipment will be cheap, since the opening-and-closing mechanism of collets are unnecessary. |

|  |

Tool holding collets

Collets for tooling systems

| ・ | Collets for tooling systems are mainly used for holding cutting tools, and the form has single taper and double taper. |

| ・ | These collets can hold in parallel even if cutting tools have dimensional variation in outside diameter, since there are flexing slots from both sides of front and back. | |

| ・ | It is not suitable for holding a workpiece since less clamping range in a free state can be taken as compared with draw back type collets. |

|  | |

|  |

Basic Technical Information On Collets

What are Spring Collets ?

Spring collets are perishable tools for fixing a workpiece at the processing, or fixing cutting tools, and used as some parts of a machine or a conveyance machine. It consists of a collet and devices, and a workpiece is that the collet included in the workholding devices open and close, and performs clamping and unclamping of a workopiece.

|  |

Spring collets are various by object works, such as size, the clamping method, and clamping force. There is a various shaped spring collets’ form as you can see the top page of a spring collets, and they are used for fix of a workpiece or cutting tools. In case of scroll chuck, a workpiece is clamped by three or four jaws. On the other hand, when we use spring collets, a workpiece is clamped as wrapping in with the number of flexing slot of the collet. Therefore, since the pressure concerning one point ends few, it can clamp powerfully, without pressure's distributing and damaging the whole clamping portion of the workpice.

Part names and functions of spring collets

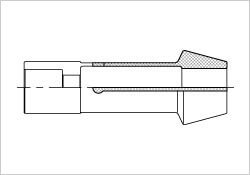

Stationary

Draw Back

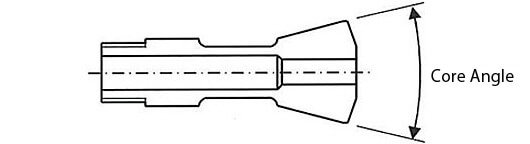

The angle of a taper

The angle of a taper is denoted by double taper. Please inform us if double taper or single taper in order not to mix up.

| * | An upper table is a typical standard. (●●●Good,●●Middle,●Low) |

| * | Please ask about detail of specifications of spring collets or workholding devices using spring collets. |