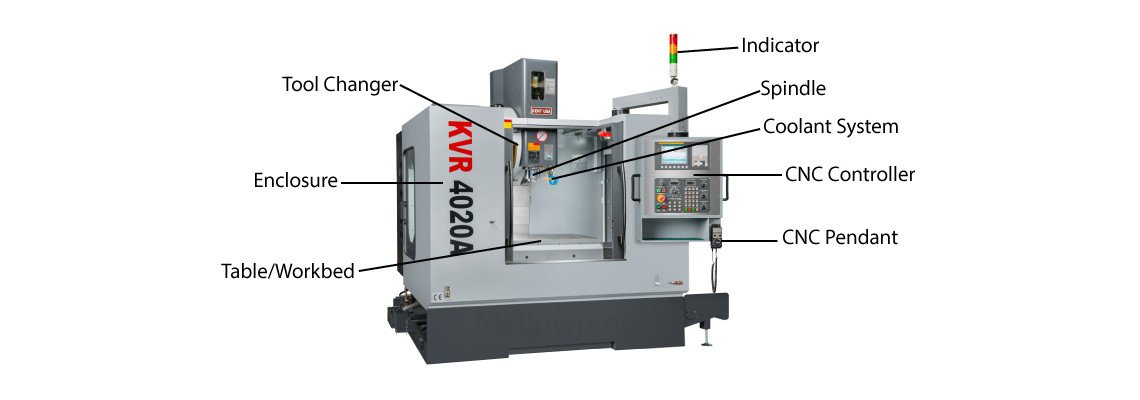

VMC machine is a Vertical Machining Center, it is a type of CNC (computer numerical control) machine that typically features a vertically oriented spindle. VMCs are used to create precision parts, typically made of metal, by removing material from a workpiece using cutting tools. They are commonly used in industries such as aerospace, automotive, and medical device manufacturing.

Some benefits of using a VMC machine include:

High precision: VMCs are capable of producing parts with very high precision due to their ability to control the movement of the cutting tools with great accuracy.

High efficiency: VMCs can perform multiple operations, such as drilling, tapping and milling, on a single machine, reducing the need for multiple operations and increasing overall efficiency.

High material removal rate: VMCs can remove material quickly and efficiently, which can help to reduce production time and increase output.

High flexibility: VMCs can work on a variety of materials, including metals, plastics, and composites, and can be programmed to create a wide range of parts.

Increased safety: VMCs can be programmed to automatically perform complex and dangerous operations, reducing the risk of injury to operators.

High repeatability : VMC machines are able to produce identical parts repeatedly with high precision and accuracy.

Cost-effective: VMCs can save costs over time due to its fast production and precision, reducing the need for manual labor and minimizing waste.

Leave a Comment