CNC (computer numerical control) programming is the process of creating a program, or set of instructions, for a CNC machine to execute a specific task, such as cutting or drilling a part. These instructions are typically written in a programming language such as G-code or M-code, and are then loaded into the CNC machine's controller, which interprets and executes the instructions to control the machine's movements.

The basics of CNC programming include:

Understanding the machine's capabilities and limitations: Before writing a program, it's important to understand the specific capabilities and limitations of the CNC machine you will be using. This includes understanding the machine's axis of motion, maximum feed rates, and maximum cutting speeds.

Creating a part model or blueprint: In order to program a CNC machine, you will need to have a detailed model or blueprint of the part you want to produce. This can be created using computer-aided design (CAD) software.

Generating toolpaths: Once you have a model of the part, you will need to generate the toolpaths, which are the specific paths that the cutting tool will follow. This can be done using computer-aided manufacturing (CAM) software.

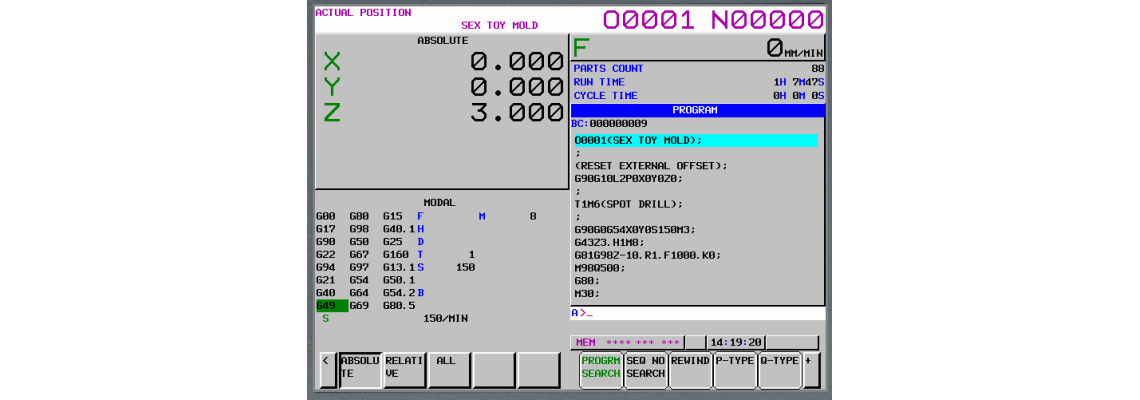

Writing the program: After the toolpaths are generated, the next step is to write the program in G-code or M-code, which is the language that the CNC machine understands.

Testing the program: Before running the program on the machine, it's important to test and verify that the program is correct. This can be done by simulating the program on the computer, or by running the program on a test piece of material.

Running the program on the machine: Once the program is verified, it can be loaded into the CNC machine's controller and executed to produce the part.

Monitoring the machine: Lastly, it is important to monitor the machine during the production process, checking for any errors or issues that may arise, and making any necessary adjustments.

19

This was a great read—informative and easy to follow. Thanks for sharing such valuable content.

The 9 Things Your Parents Taught You About Car Key Housing Repair Car Key Housing Repair

The Time Has Come To Expand Your Robot Cleaners Uk Options Buy Robot Cleaner

10 Quick Tips About Smart Vacuum robotic Floor sweeper

The 10 Most Terrifying Things About Laser Cut Key Repair Laser Cut Key Repair

Robot Cleaner Uk Tools To Ease Your Everyday Lifethe Only Robot Cleaner Uk Trick Every Individual Should Learn Robot Cleaner

Five Robot Vacuum Projects For Any Budget Robot vacuum cleaner

Guide To Vacuum Robot: The Intermediate Guide Towards Vacuum Robot Vacuum robot

14 Questions You Might Be Insecure To Ask About Robotic Hoover Robotic Hoover And Mop (Http://T.044300.Net/)

The 10 Scariest Things About Floor Robot Floor Robot

What Is Buy Robovac And Why Is Everyone Talking About It? Robot Vacuum

The 10 Most Scariest Things About Robotic Vacuum Robotic vacuum

The History Of Robot Vacuum Cleaner Robot Vacuum Cleaners (Diego-Maradona.Com.Az)

What's The Current Job Market For Best Automatic Vacuum Cleaner Professionals Like? Best Automatic Vacuum Cleaner; Chessdatabase.Science,

Why Robot Cleaners Uk Is Still Relevant In 2024 Buy Robot Cleaner

5 Laws Everybody In Best Automatic Vacuum Cleaner Should Be Aware Of Automatic Vacuum Cleaners

15 Best Robot Vacuum Cleaner Dog Hair Bloggers You Need To Follow Best Robot Vacuum Cleaner

See What Robot Vacuum Cleaners Uk Tricks The Celebs Are Making Use Of robot vacuum cleaners (https://md.chaosdorf.de/)

20 Things You Should To Ask About Robot Vacuum Prior To Purchasing Robot Vacuum Smart Floor Cleaner

Leave a Comment