- Stock: In Stock

- Model: DIN 1809

- Weight: 1.00kg

- Manufactured: In India

- Shipping: Worldwide

- MPN: TE8920040888

- Dispatching From: Chennai, India

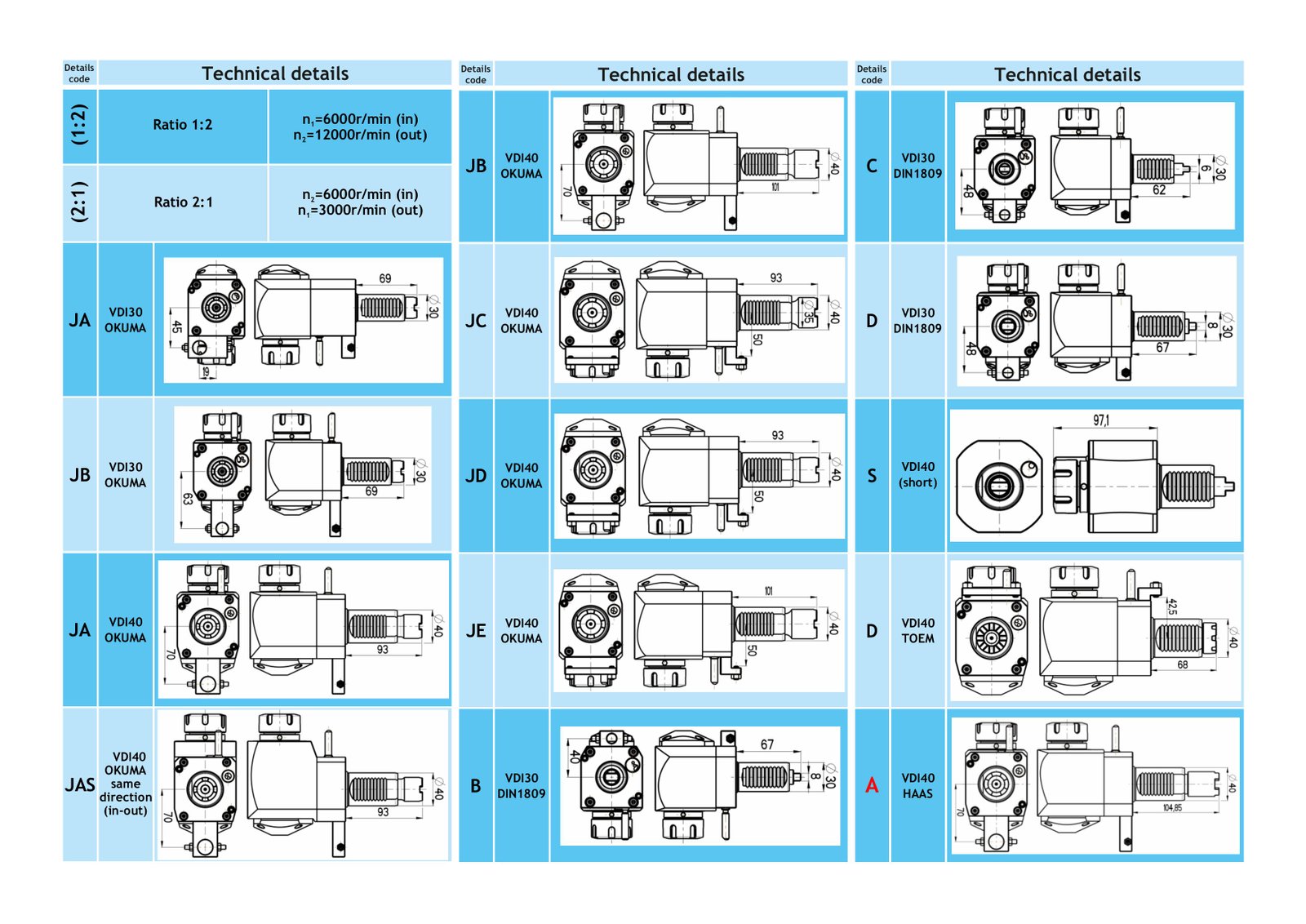

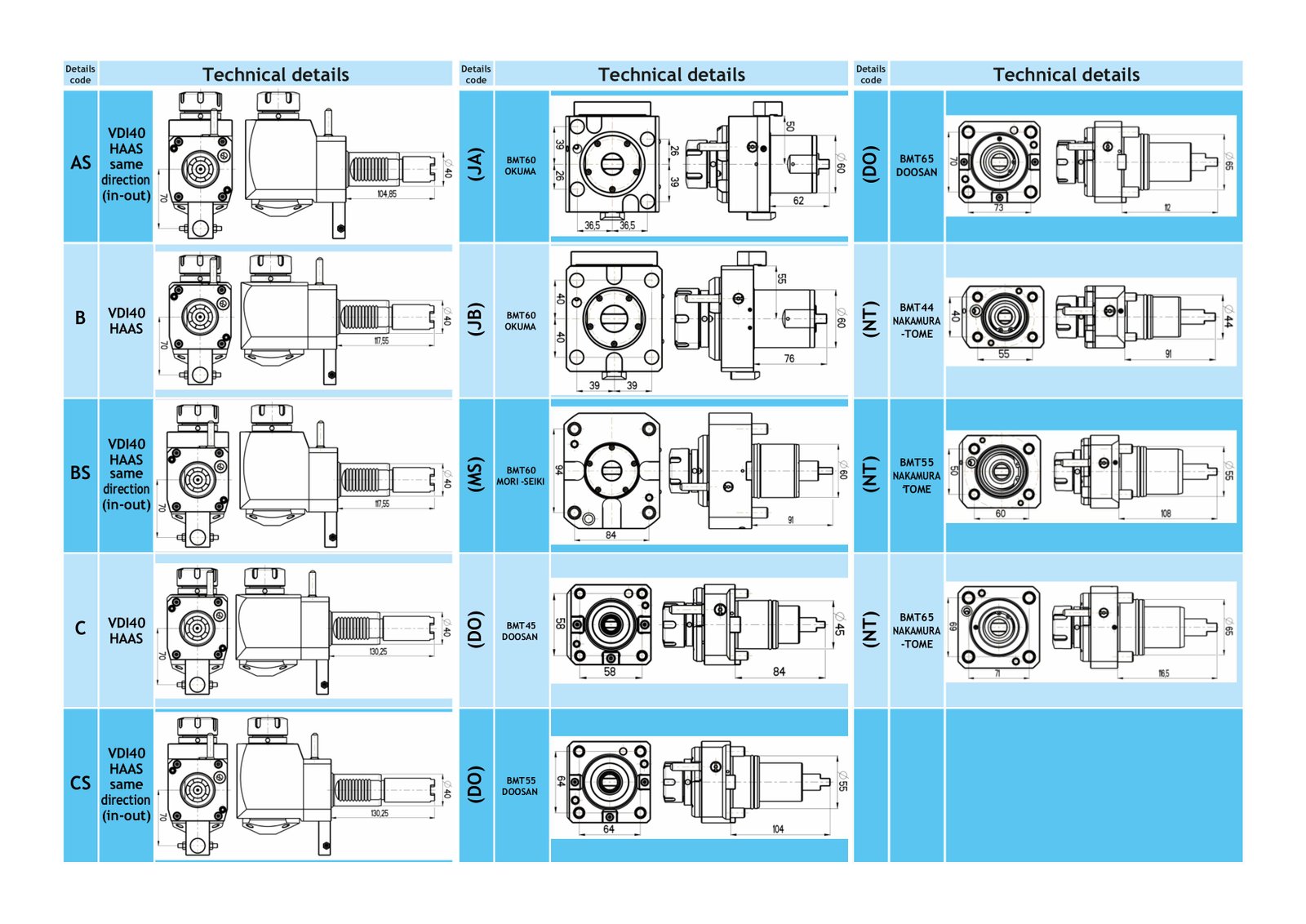

- Dimensional & Technical Specifications

- Frequently Asked Questions (FAQ)

- We Offer Worldwide Shipping

- Reviews

| NEW PRODUCTS |

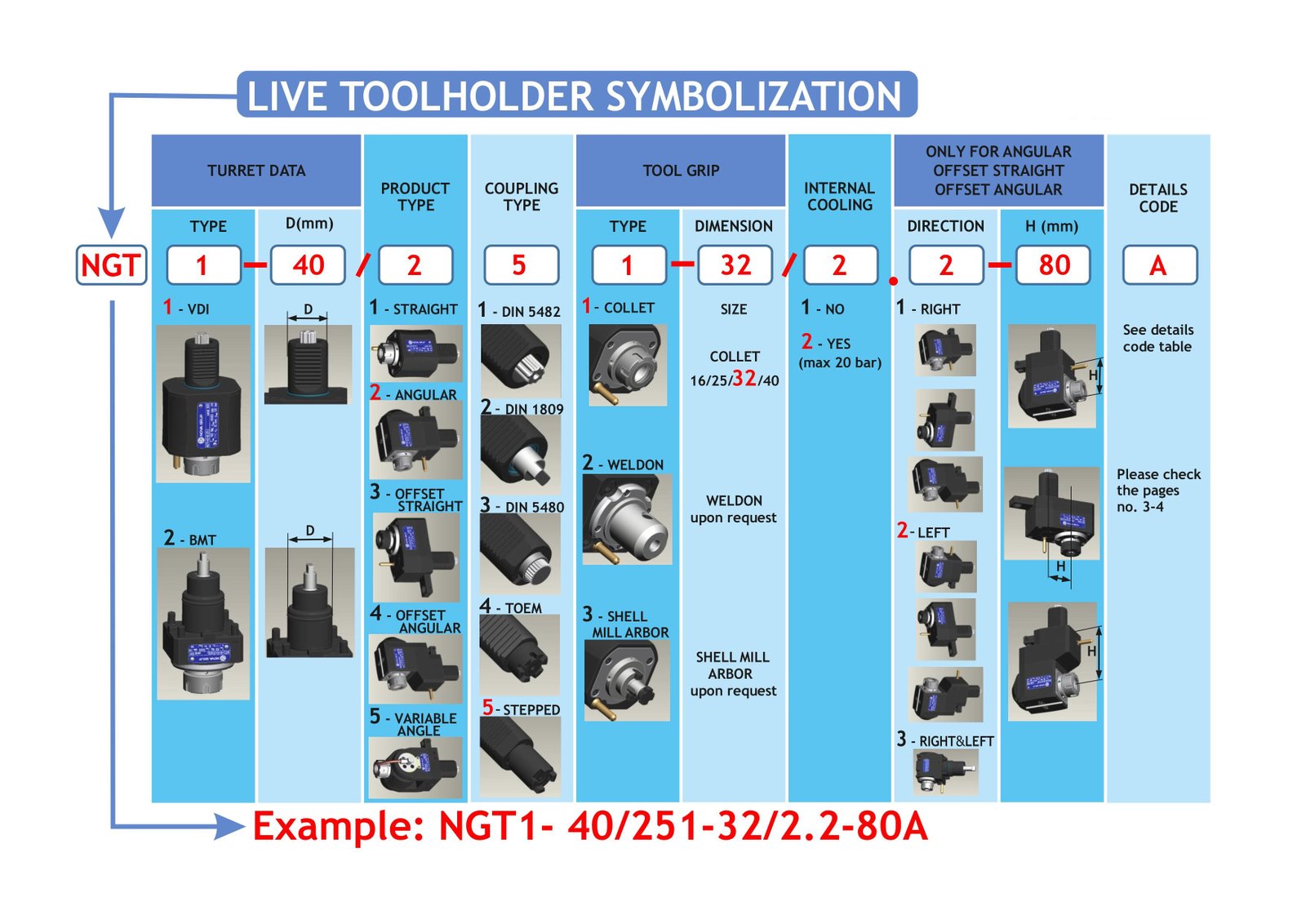

EXTREME LIVE TOOLHOLDERS |

| TURRET INTERFACE TYPE |

VDI |

| SHANK SIZE [mm] |

40 |

| DRIVE COUPLING TYPE |

DIN 1809 |

| TYPE OF INSIDE BEARINGS |

Spindle Ball Bearings |

| BEARING TYPE | High Speed Ball Spindle |

| COOLANT |

Internal 80bar |

| TOOL GRIP DIMENSION |

Collet ER25 |

| TOOL GRIP TYPE |

COLLET |

| TRANSMISSION RATIO [i=n1:n2] |

1:1 |

| TORQUE [Nm] |

50 |

| Compatible machines |

Alex-Tech > VT28-28BL (DISC) BATLIBOI > Sprint 25TC (DISC) Biglia > B111 VDI40 (DISC) Biglia > B200 VDI40 (DISC) Biglia > B56 VDI40 (DISC) Chevalier > FCL-1028MC (DISC) CHING HUNG > CL260 (DISC) CHING HUNG > CL38 (DISC) Cincinnati > HTC200 (DISC) Cincinnati > HTC250 (DISC) CNC Takang > TNC-2000DST (DISC) CNC Takang > TNC-30N (DISC) Daewoo > PUMA 200 MS (DISC) Daewoo > PUMA 250 MS (DISC) Duplomatic > VDI40 1809 (DISC) EMCO > ET500 (DISC) Fadal > PTC250 (DISC) Fair Friend > FTC-20 (DISC) Fair Friend > FTC-30 (DISC) Focus CNC > FCL 300MC (DISC) Hardinge > Talent 10/78 (DISC) Hitachi Seiki > CS20/CS25 (DISC) Hitachi Seiki > Hicell 23S (DISC) Hitachi Seiki > HT 200/250 (DISC) Hitachi Seiki > HT 20S (DISC) Hitachi Seiki > HT 23R (DISC) Hitachi Seiki > HT 25G (DISC) HURCO > TMM10 (STAR) HURCO > TMM10i (STAR) HURCO > TMX10 MY/MYS 1809 (STAR) HURCO > TMX8 MY/MYS 1809 (STAR) Hyundai WIA > Hit 20M/200M/250M (DISC) Kovosvit MAS > S50 VDI40 (DISC) Leadwell > LTC 25 BLM (DISC) Leadwell > T8 M (DISC) Magdeburger > M120 (DISC) Romi > G30M 1809 (DISC) Romi > GL250M (DISC) Romi > GL280M (DISC) Romi > GL300M (DISC) Saeilo > Contur LT-20 MC (DISC) SOMAB > Transmab 500 (DISC) Taksan > TTC630 Duplomatic (DISC) TOPPER > TB 25YMBC DIN1809 (STAR) YCM > GT250 MA/LMA/MB/LMB (DISC) YCM > GT300 MA/LMA/MB/LMB (DISC) |

TOOLHOLDERS INSTRUCTIONS

Thank you for choosing our products.

For best results, please follow below instructions.

GENERALITIES

Each toolholder has passed a QC test and has a documented specification, attesting his geometric precision.

Our toolholders are equipped with high-quality sealed bearings that ensure a long service life. The grease that is used is Kluber or Isoflex.

Each toolholder is checked for temperature and vibration parameters on the test bench. This means that the toolholder is ready to start working in the production process!

PLEASE NOTE

Keep these instructions, with care, to have them whenever needed for consultation.

Be aware of any state law to avoid accidents for yourself and others by using live toolholders. Be careful when handling the toolholders to prevent it from falling, which could cause injury to yourself and others. Until the toolholder is attached to the turret, use rubber or plastic tool sleeves to avoid injuries caused by the tool cutting sharp edges.

If the toolholders are overloaded, there may be major damage in the operation of the product. In this brochure it is using symbolic representations. Some accessories shown are not included, as standard, with delivered toolholders.

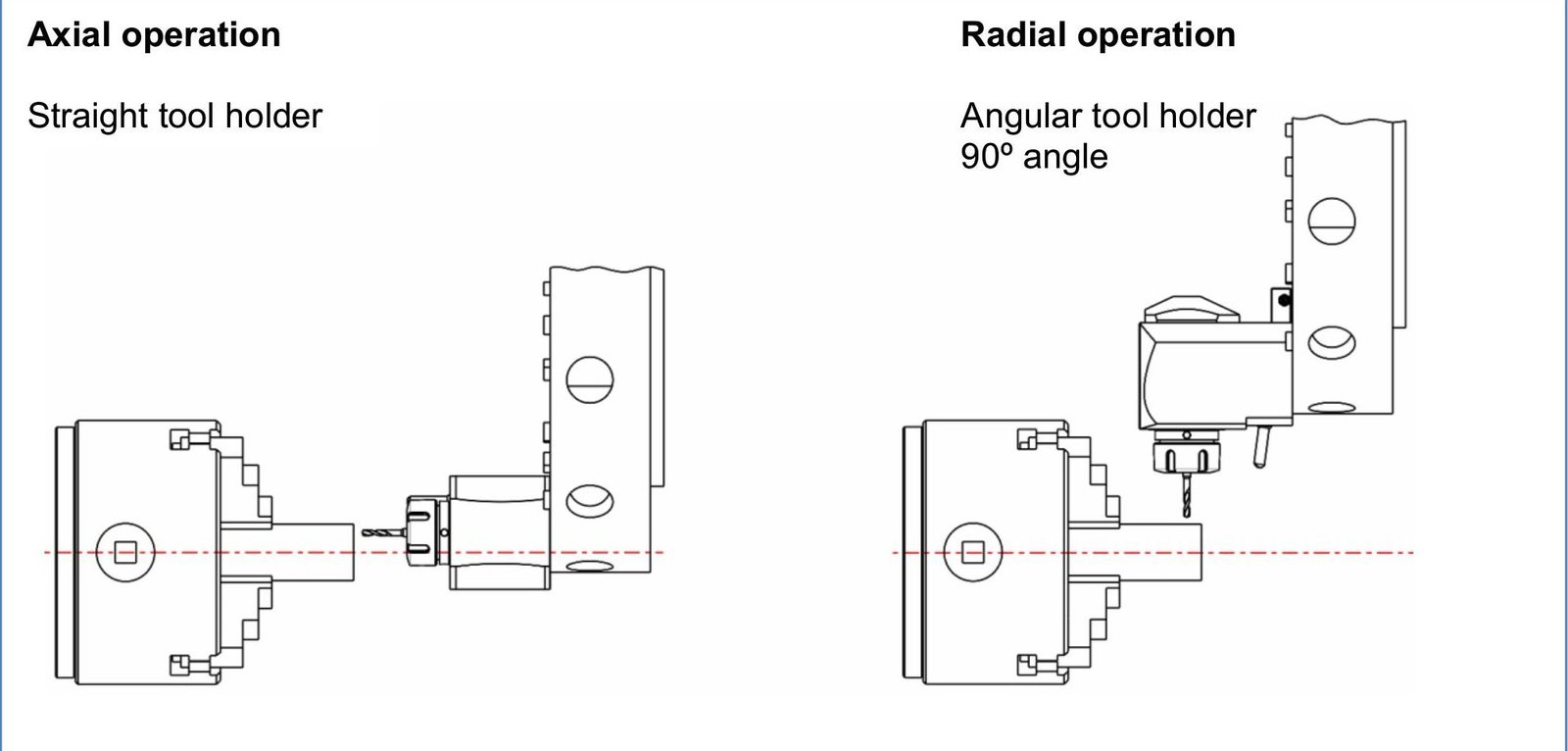

1. INSTALLATION AND FUNCTIONING

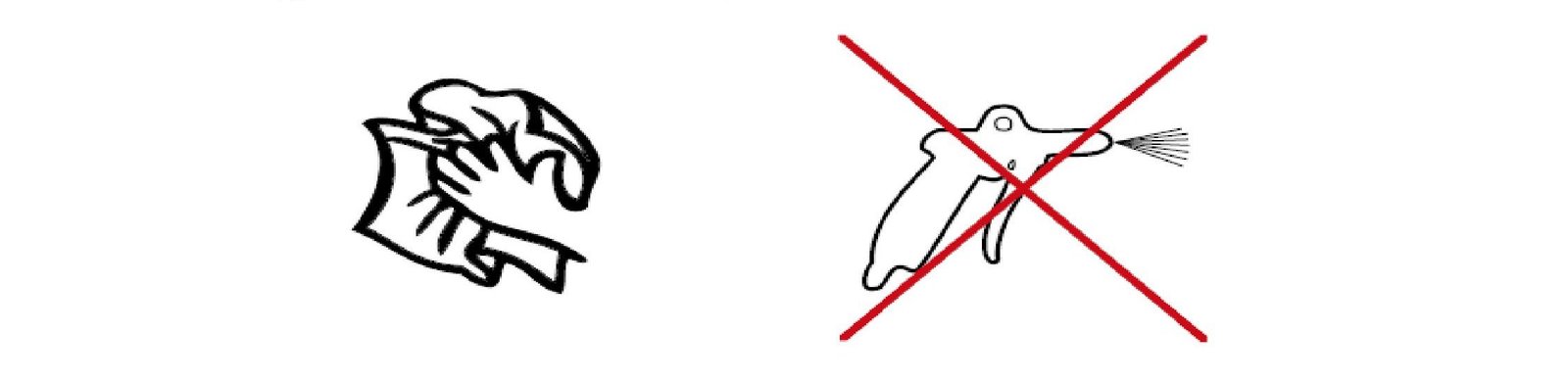

1.1 Cleaning and care

For cleaning, use a soft cloth. Do not use compressed air to clean the toolholders.

To achieve a long life of toolholders, please do not use strong chemical cleaners. Protect the surfaces of the toolholders with oil or other anti-corrosion products during storage.

1.2. Transmission, bearings and lubrication

Bearings and gears are lubricated with high quality lubricants for the lifetime of toolholder. Any additional lubrication is not required under normal operating conditions.

Additional data such as torque, maximum speed, etc. can be taken from the product datasheet.

1.3. Fixing on the turret

In principle, in order to guarantee an optimal function of the toolholder, a clean surface of the turret interface and the couplings is required. Only this ensures the highest possible accuracy in the cutting process.

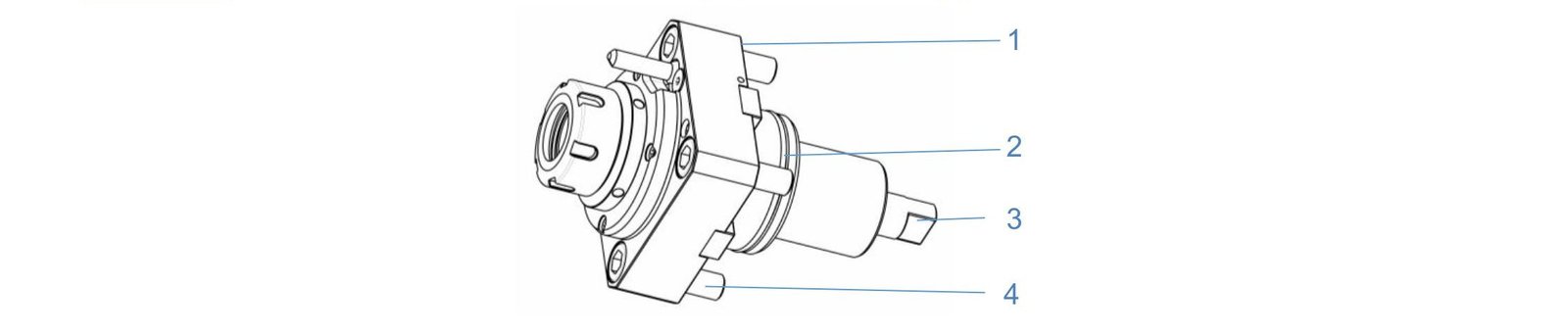

1.3.1. Mounting the toolholders on the turret

Please inspect the contact surface of the turret (7). It must be clean and without chips.

Please check that the ring O-ring (8) is not damaged.

Insert the cylindrical part of the toolholder into the turret. Please ensure that the drive shaft (9) engages with the turret drive.

Enter the toolholder inside turret until the interface contact is well done. Ensure the toolholder is firmly tightened.

BMT turret: Mount the holder on turret and firmly tighten the bolts (4).

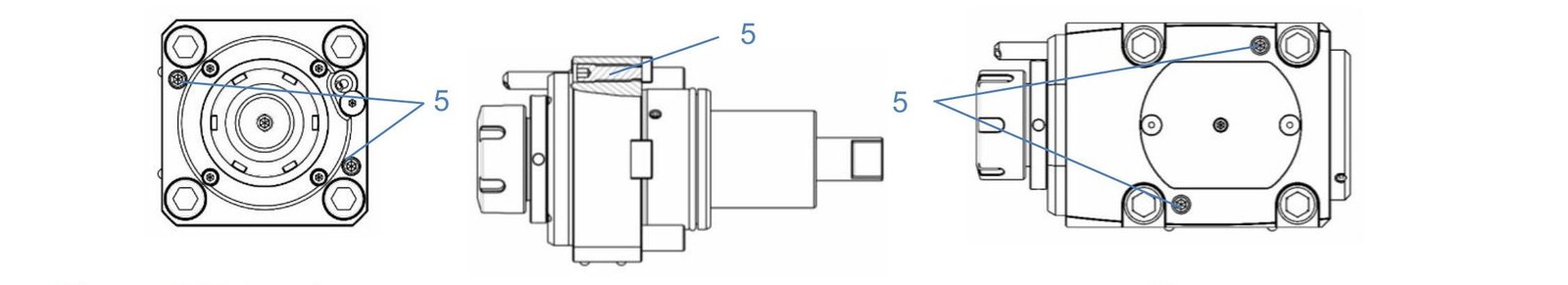

In order to remove the toolholder from the turret, just rotate the two set screws (5) clockwise. After the toolholder is released, you must rotate back the set screws until they are positioned below the mating surface of the toolholder with the turret, see picture above.

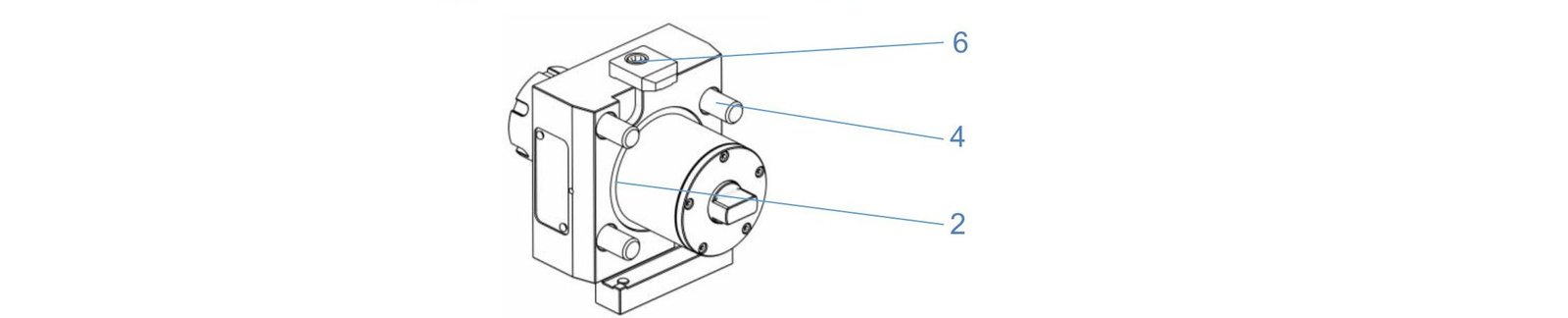

Okuma BMT turret: Mount the toolholder on turret and slightly tighten the bolts (4). The toolholder will be

centered by tighten the screw (6). Tighten firmly the screws (4).

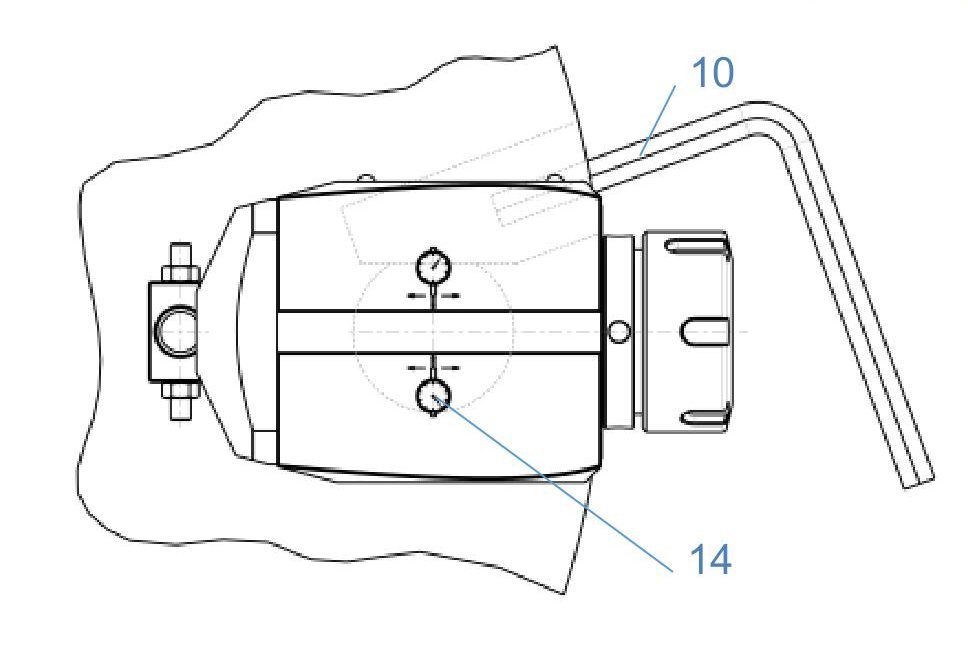

VDI turret: mount the holder on turret and tighten the rack screw with the hexagon key (10) firmly.

NOTE: The coupling of toolholder must be aligned with similar coupling from inside turret interface. If the

toolholder cannot easily be inserted into the turret, then remove the toolholder from the turret surface. In this

case, please use the machine's operating instructions.

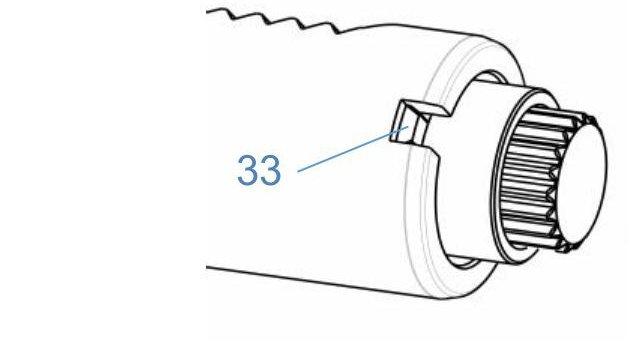

Particular case: for Live Toolholders with coupling type DIN 5480, for making

coupling, toolholder’s shaft need to be in locked position, so no rotation. This

position is realized when ring beak (33) is in position from this picture.

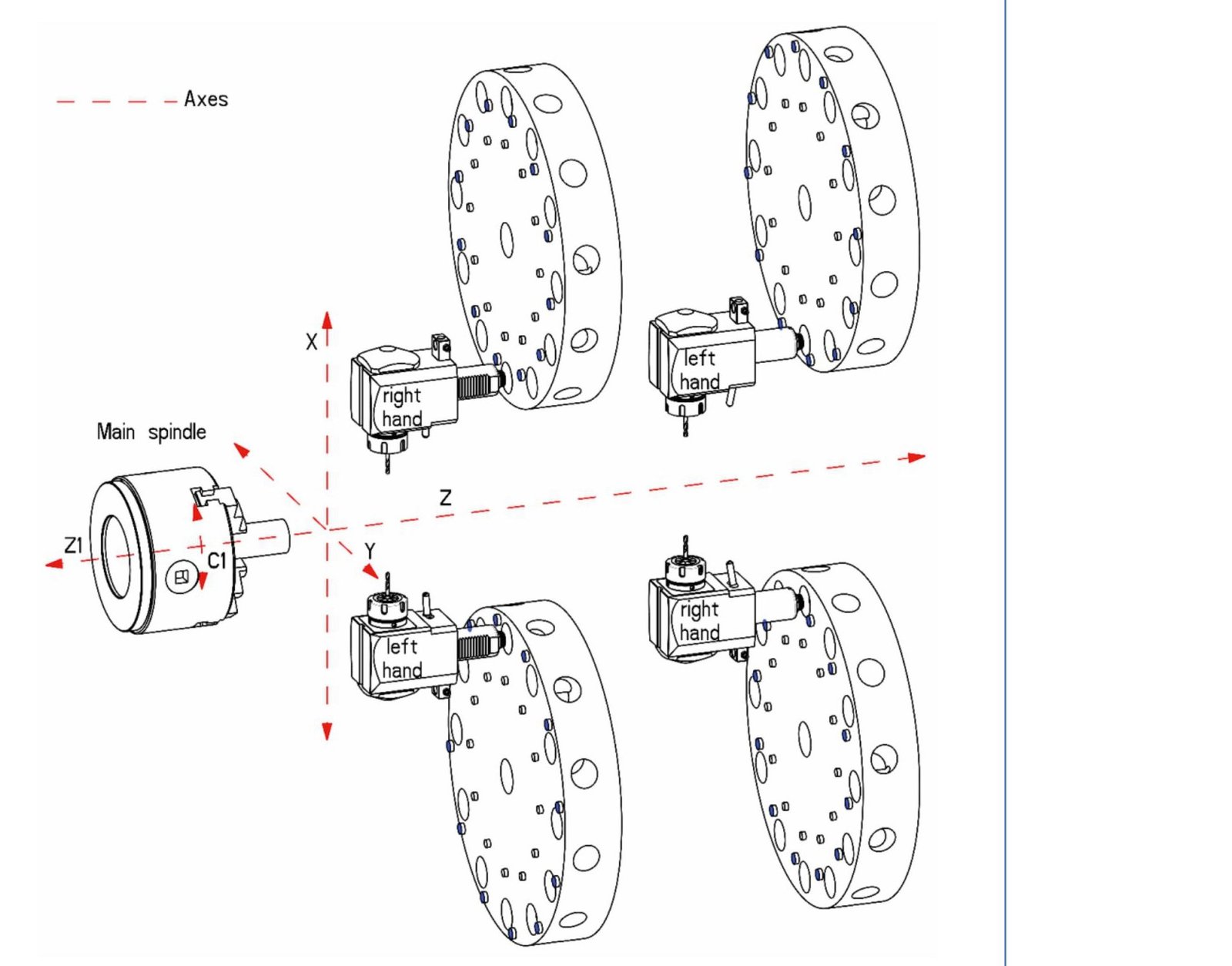

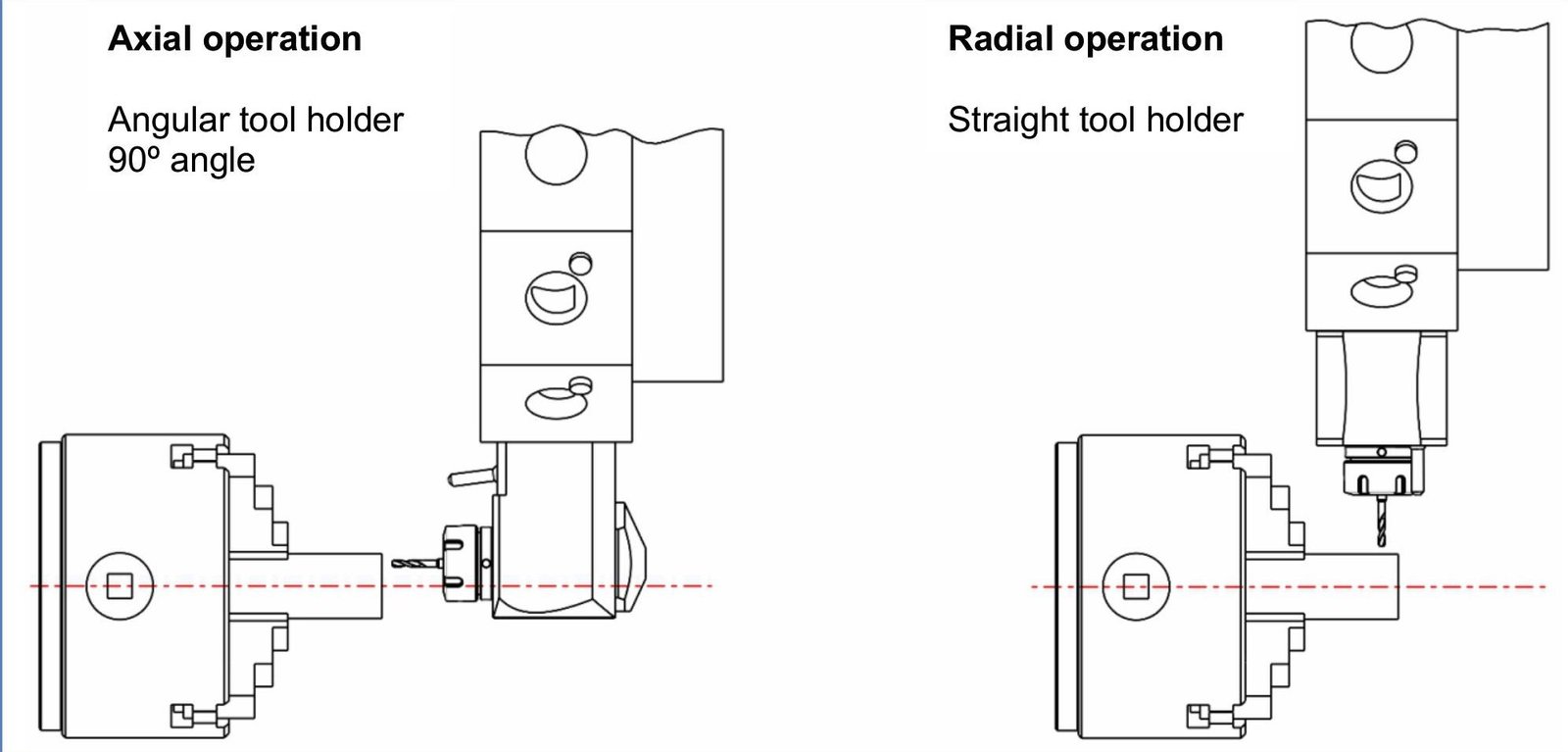

1.3.2. Aligning the VDI angular toolholder

The angular toolholders can be equipped for alignment with one of the following systems:

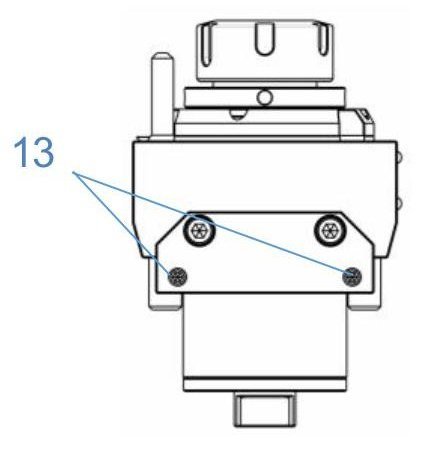

The toolholder will be set as follows: gently squeeze the toolholder on the turret through toothed rack in the recess by tightening a hex key (10) to allow the alignment. Align the toolholder with a dial comparator clock (14), by displacing it along the whole length of aligning area (surface), using for adjusting threaded pins (12). Once you have aligned the toolholder, you must tighten the threaded pins (12) and secure them with nuts (13), then firmly tighten the rack screw with the hexagon key (10).

At the end of alignment operation check again position set-up.

1.3.3. Aligning the Okuma BMT toolholder

The toolholders do not need any setup, but if from some reasons you need to fine tune the position of the toolholder then you have 2 screws (13), to do this job. You must do this setup before the final tightening of the screws (4).

1.4. Variable Angle Toolholder - Angle setting

The screws (15) will be loosen. Set the desired angle and firmly tighten the screws (15). Check the set angle, with a Digital Angle Finder or a Protractor, measuring by comparison the angle between the cutting tool and axle of the spindle (chuck).

1.5. Clamping the tool

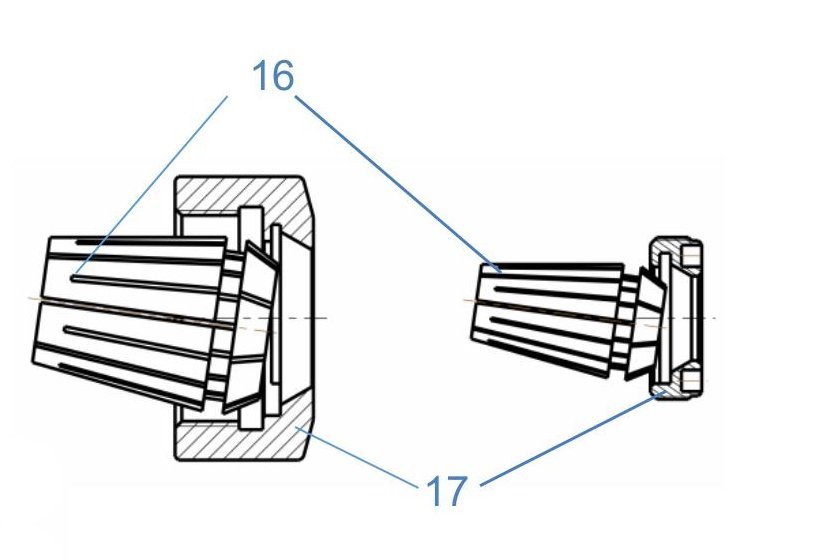

1.5.1. Fixing the cutting tool in collet

Insert the collet (16) into the ER clamping nut (17) until it enters inside locking way.

Firmly tighten the ER clamping nut using 2 (two) keys, as in bellow picture.

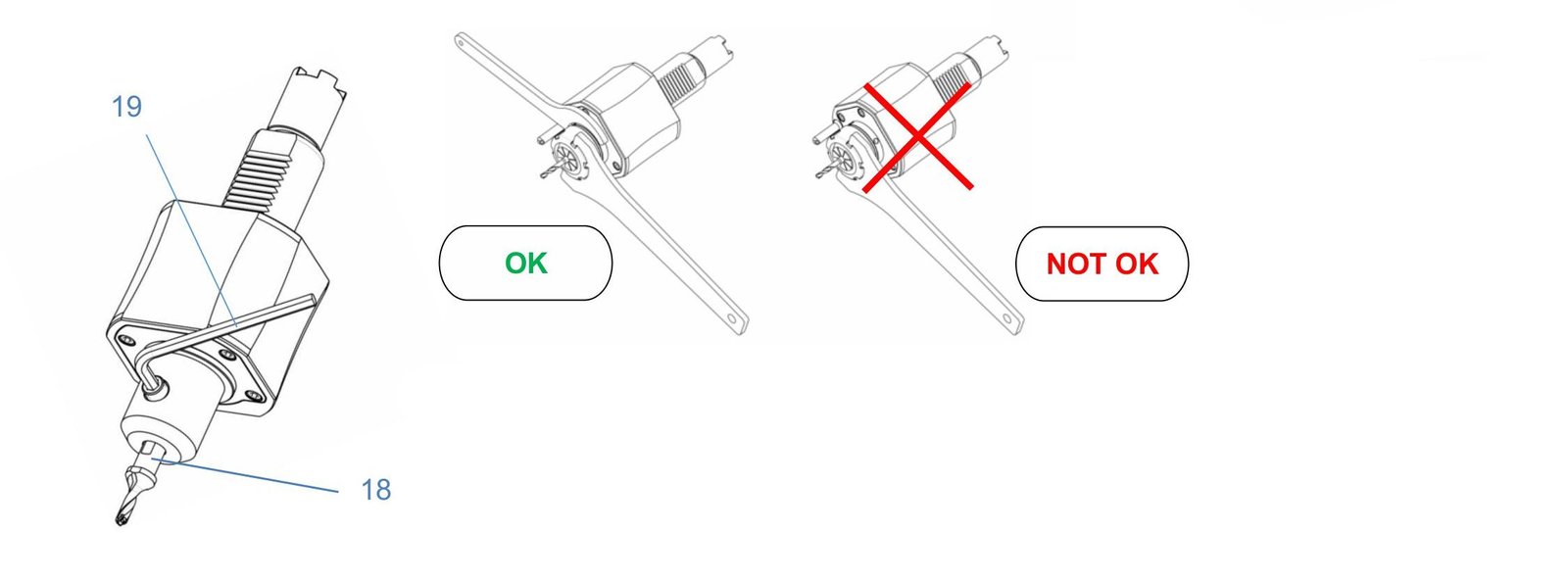

1.5.2. Fixing the cutting tool in Weldon output

Insert the cutting tool (18) (with the milled surface against the retaining pin) into the shaft hole and lock with the threaded pin using the hexagon key (19).

1.6. Cooling system of the Toolholder

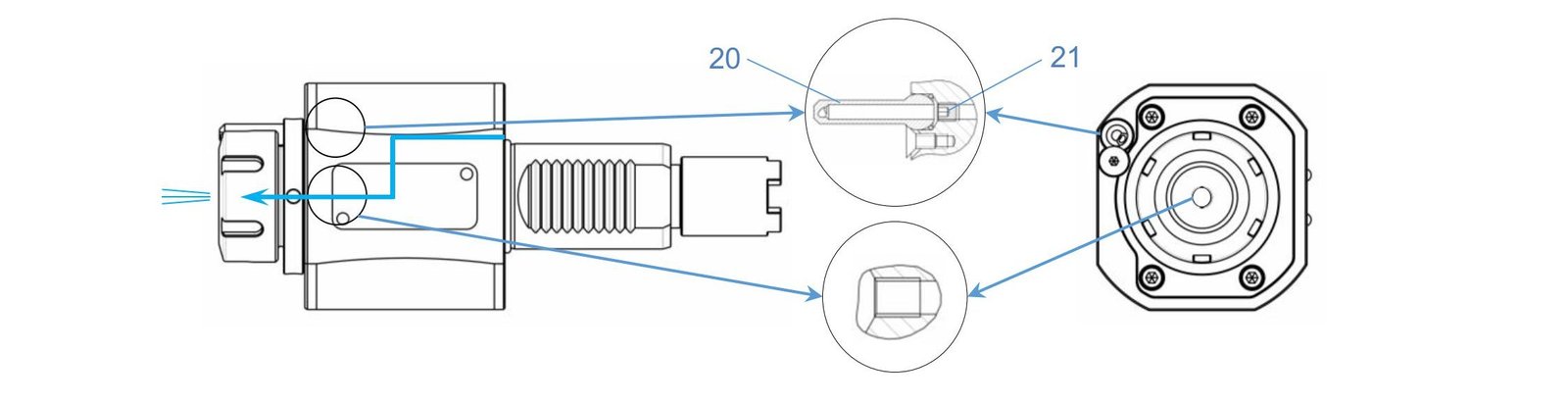

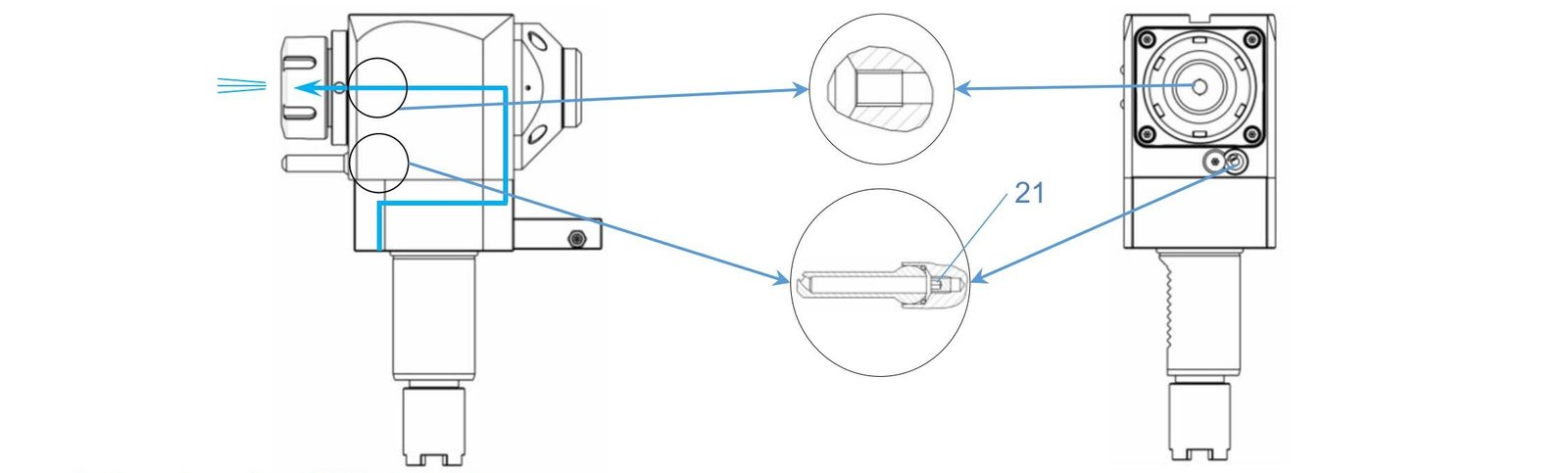

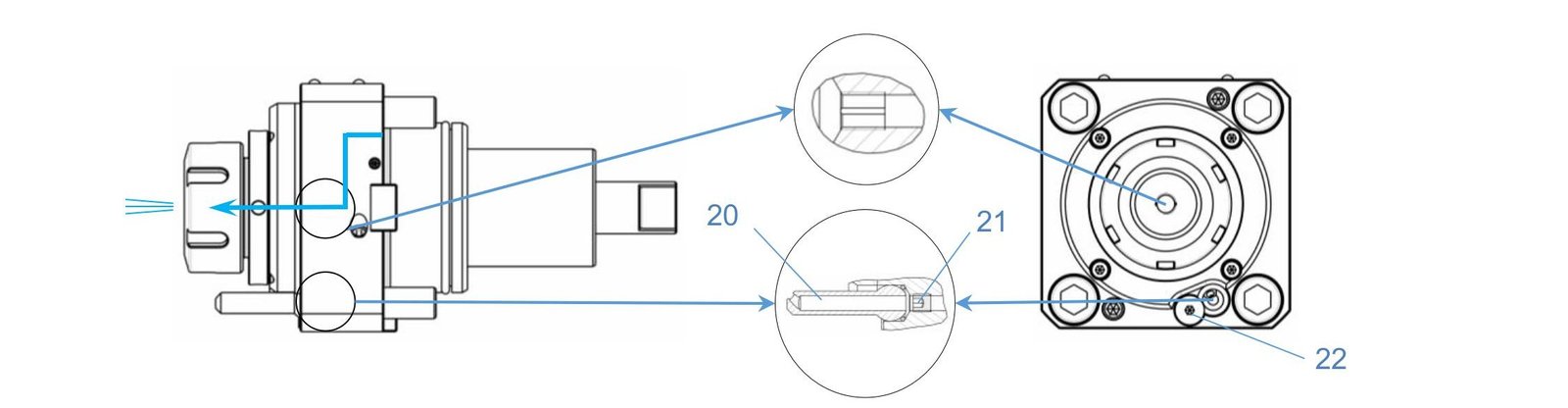

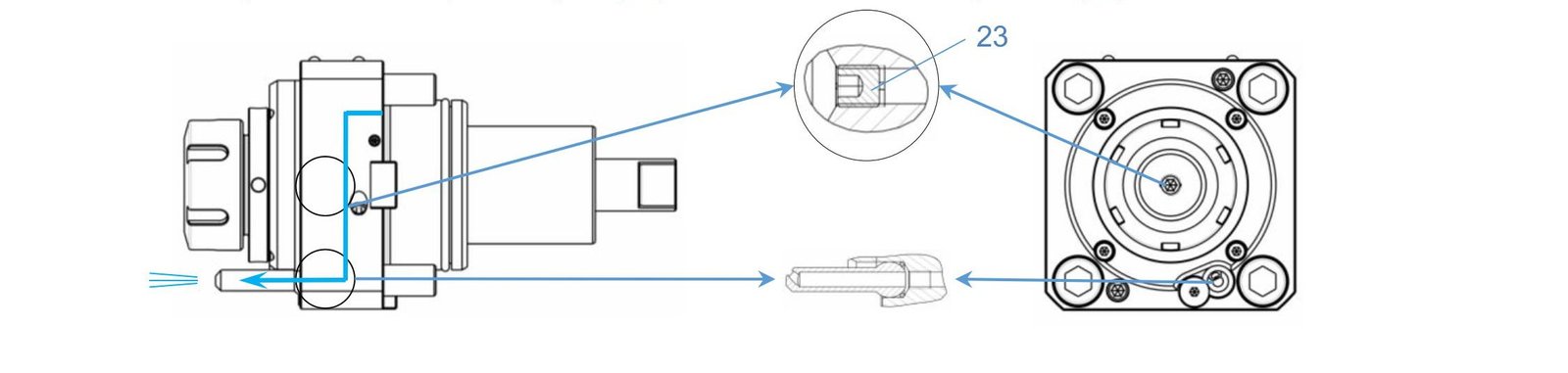

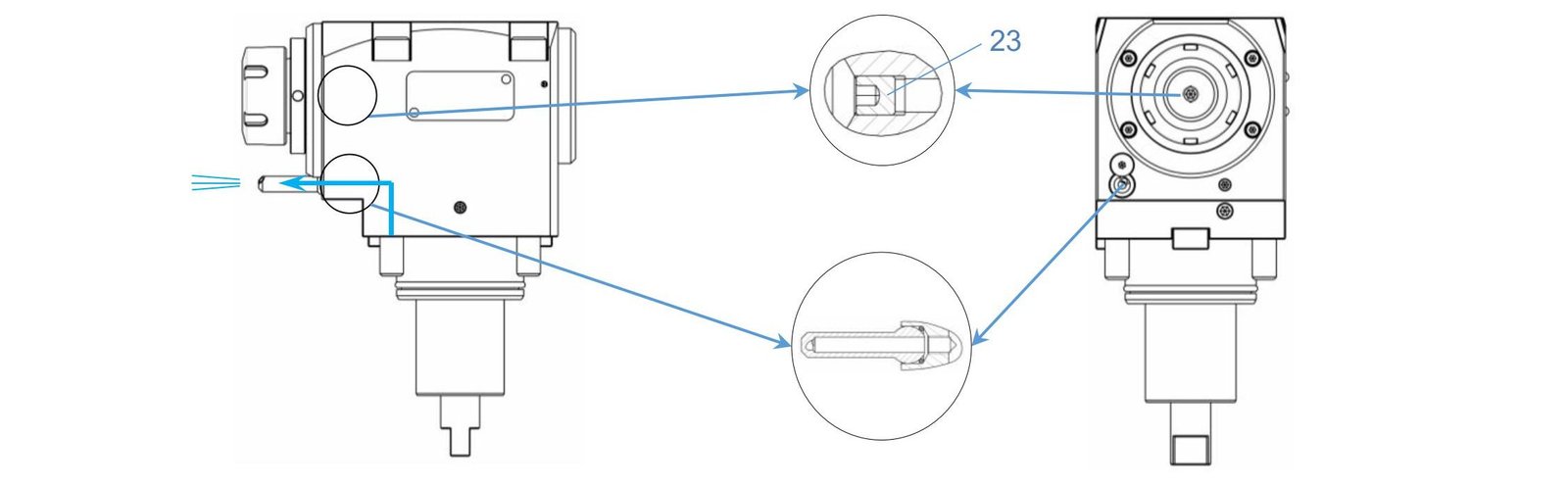

Internal cooling (VDI straight): The toolholders with internal cooling are prepared for this option from factory.

Toolholders provide coolant through the shaft, respectively by the cutting tool. For the internal cooling of the

cutting tool, remove the plug (23) with a hexagon Allen key and put in place the plug (21).

External cooling (VDI straight): Toolholders provides coolant through pipes. For external cooling you have to:

Remove the plug (21) using a hexagonal Allen key and put in place the plug (23). Adjust the orientation of the

external cooling fluid with the spherical joint (20) and fasten it with setting screw (22).

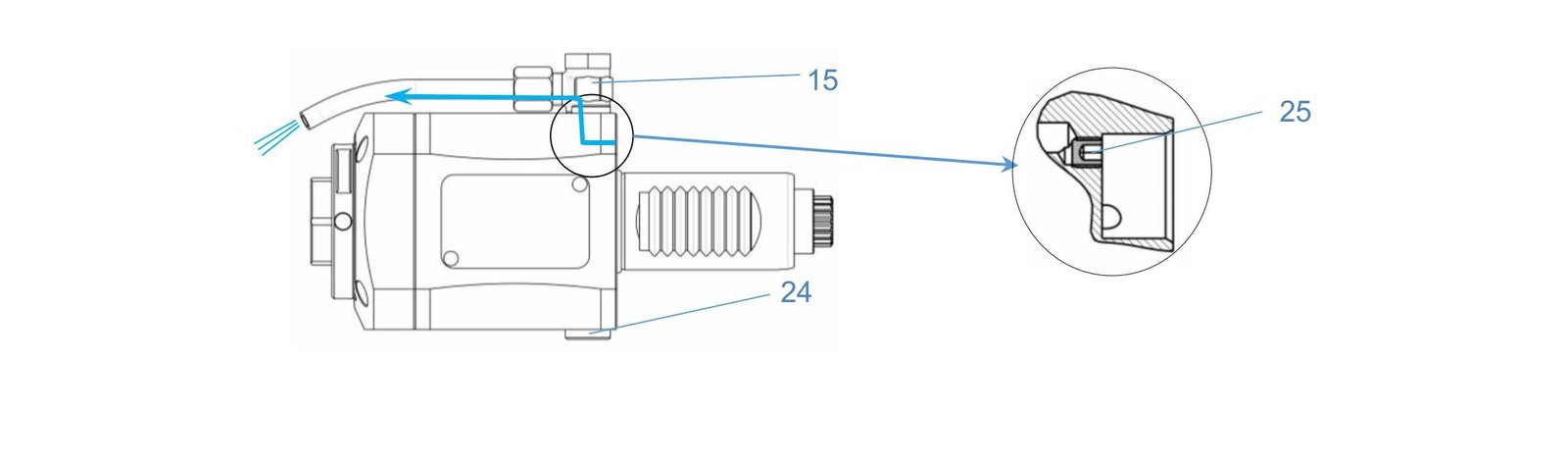

Internal cooling (VDI straight ): The toolholders with internal cooling are prepared for this option from factory.

Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal cooling of the

cutting tool, remove the plug (25) with a hexagon Allen key and put in place both plugs (24) removing the pipe

assembly (15).

External cooling (VDI straight ): Toolholders provides coolant through pipes. For external cooling you have to:

insert the plug (25) using a hexagonal Allen key, replace one of the two plugs (24) with the pipe assembly (15) and

adjust the orientation of the external cooling fluid from 90 degree fitting and the pipe.

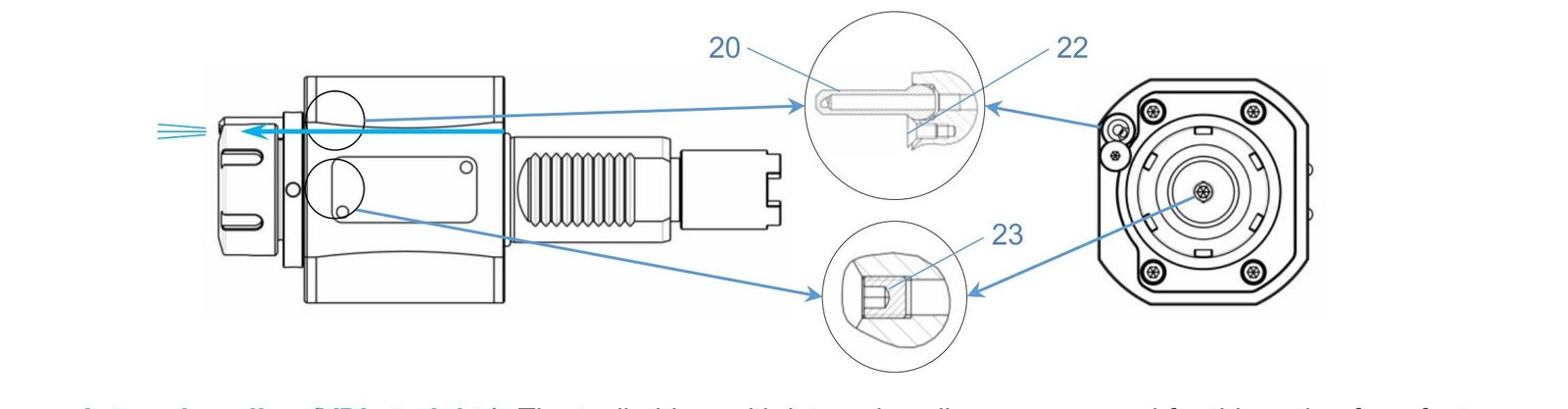

Internal cooling (VDI angular): The toolholders with internal cooling are prepared for this option from

factory. Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal cooling

of the cutting tool, remove the plug (23) with a hexagon Allen key and put in place the plug (21).

External cooling (VDI straight): Toolholders provides coolant through pipes. For external cooling you have to:

Remove the plug (21) using a hexagonal Allen key and put in place the plug (23). Adjust the orientation of the

external cooling fluid with the spherical joint (20) and fasten it with setting screw (22).

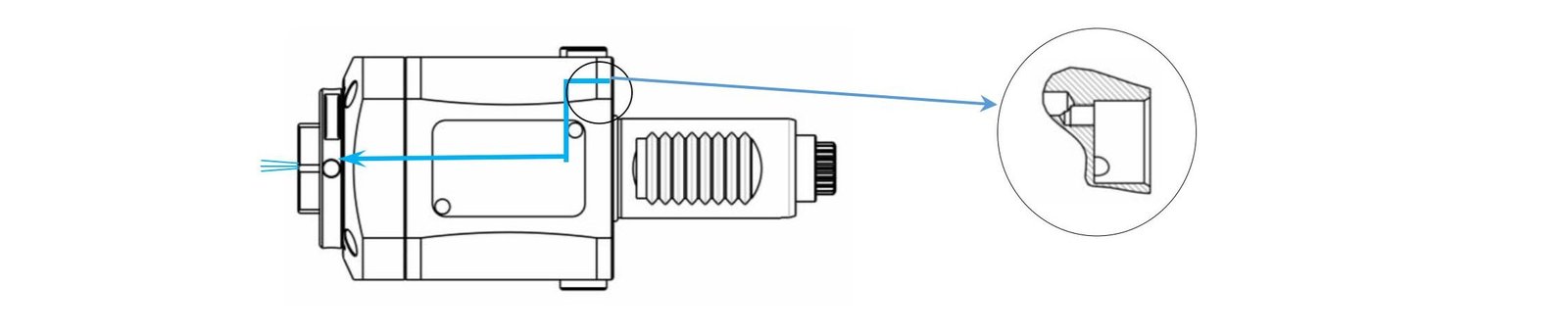

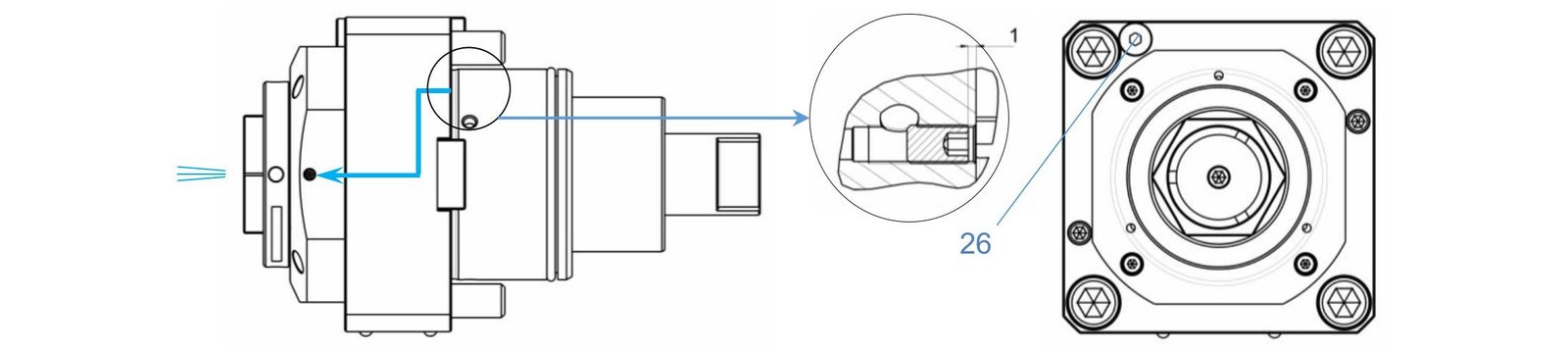

Internal cooling (BMT straight): The toolholders with internal cooling are prepared for this option from factory.

Toolholders provide coolant through the shaft, respectively by the cutting tool. For the internal cooling of the

cutting tool, remove the plug (23) with a hexagon Allen key and put in place the plug (21).

External cooling (BMT straight): Toolholders provides coolant through pipes.For external cooling you have to:

Remove the plug (21) using a hexagonal Allen key and put in place the plug (23). Adjust the orientation of the

external cooling fluid with the spherical joint (20) and fasten it with setting screw (22).

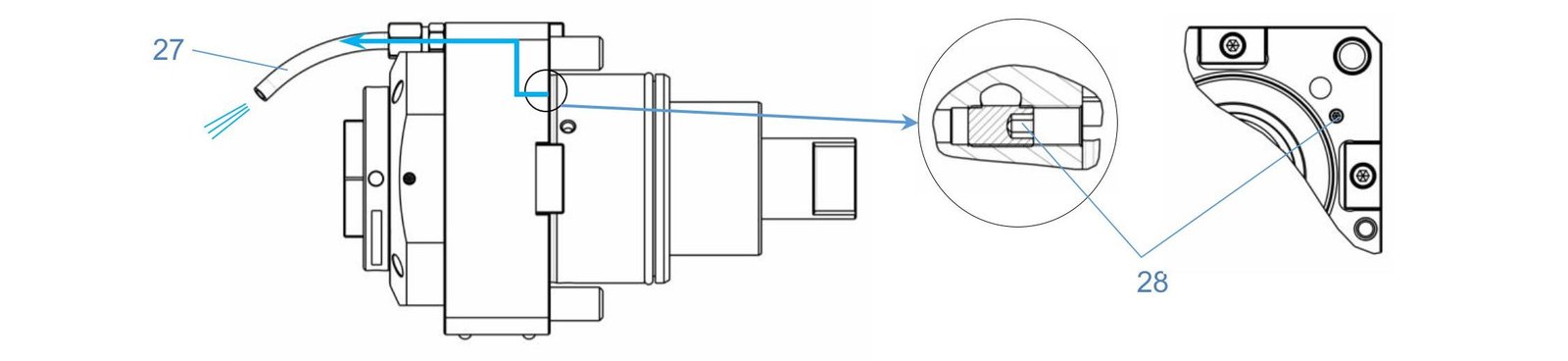

Internal cooling (BMT angular): The toolholders with internal cooling are prepare for this option from

factory. Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal cooling

of the cutting tool, remove the plug (23) with a hexagon Allen key and put in place the plug (21).

External cooling (BMT straight): Toolholders provides coolant through pipes.For external cooling you have to:

Remove the plug (21) using a hexagonal Allen key and put in place the plug (23). Adjust the orientation of the

external cooling fluid with the spherical joint (20) and fasten it with setting screw (22).

Internal cooling (BMT straight): The toolholders with internal cooling are prepared for this option from

factory. Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal cooling

of the cutting tool, rotate counterclockwise the plug (28) with a hexagon Allen key and put in place the plug (26).

External cooling (BMT straight): Toolholders provides coolant through pipes. For external cooling you

have to: rotate clockwise the plug (28) until the end of the thread, using a hexagonal Allen key, replace the plug

(26) with the pipe assembly (27) and adjust the orientation of the external cooling fluid from fitting and the pipe.

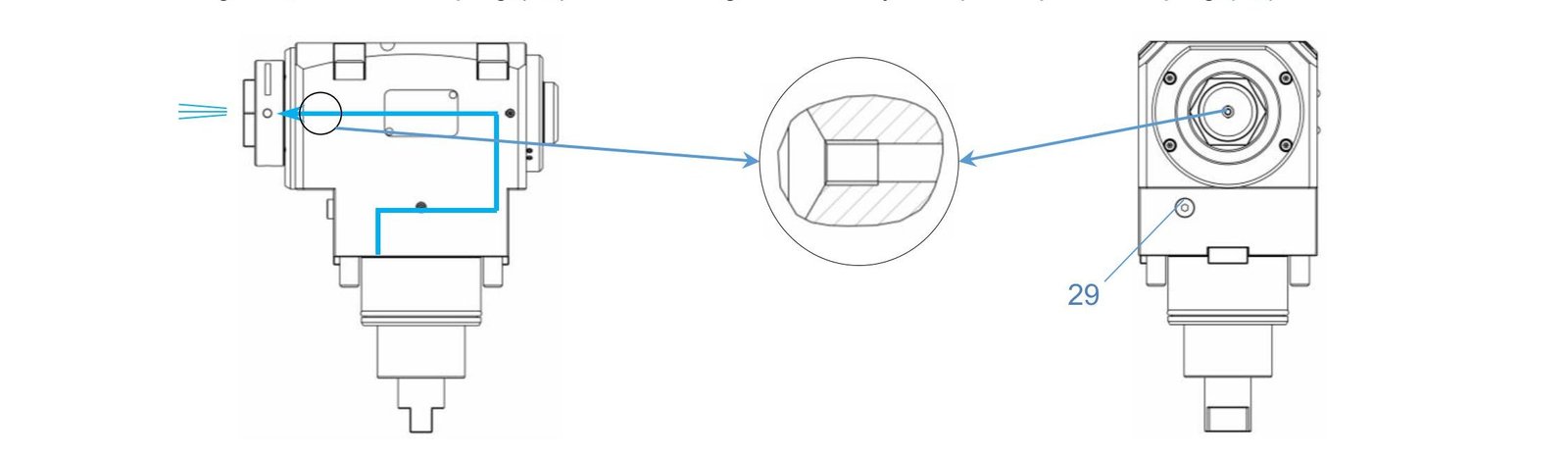

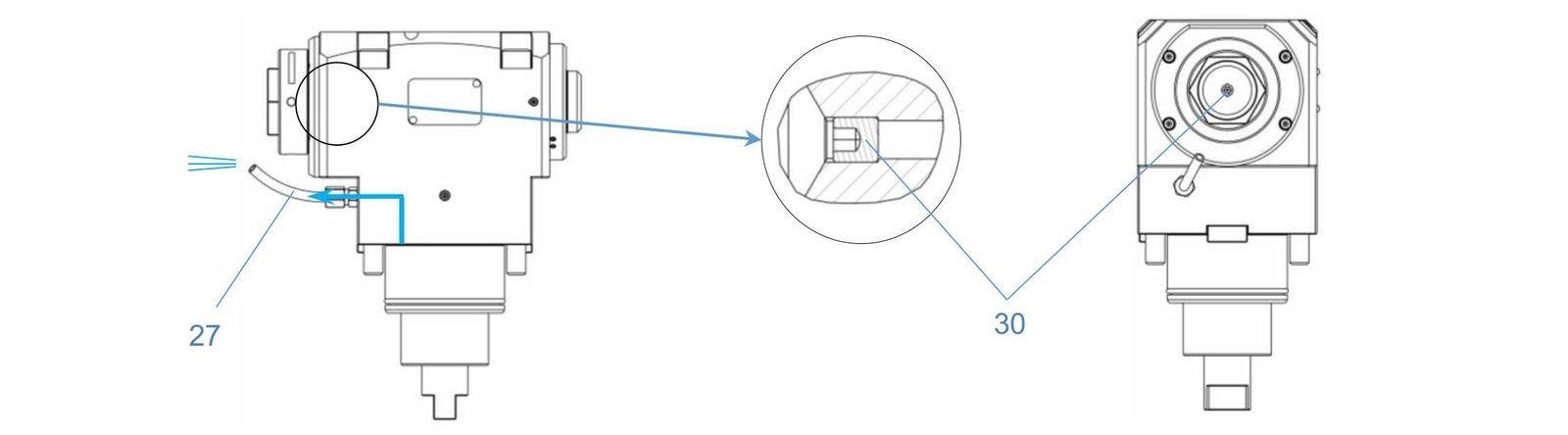

Internal cooling (BMT angular): The toolholders with internal cooling are prepared for this option from

factory. Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal cooling

of the cutting tool, remove the plug (30) with a hexagon Allen key and put in place the plug (29).

External cooling (BMT angular): The toolholders with internal cooling are prepared for this option from

factory. Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal cooling

of the cutting tool, remove the plug (30) with a hexagon Allen key and put in place the plug (29).

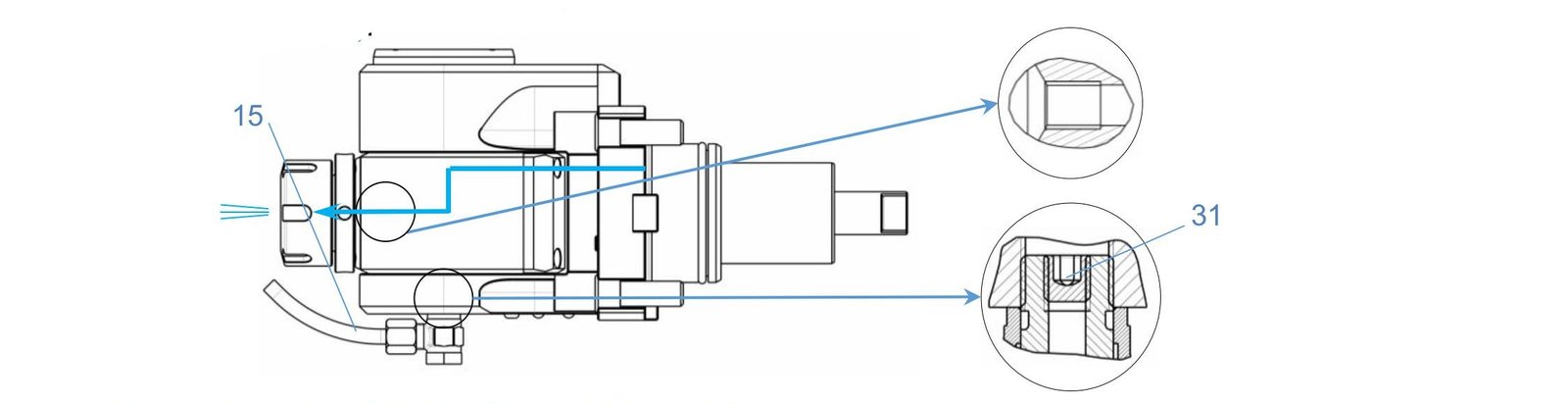

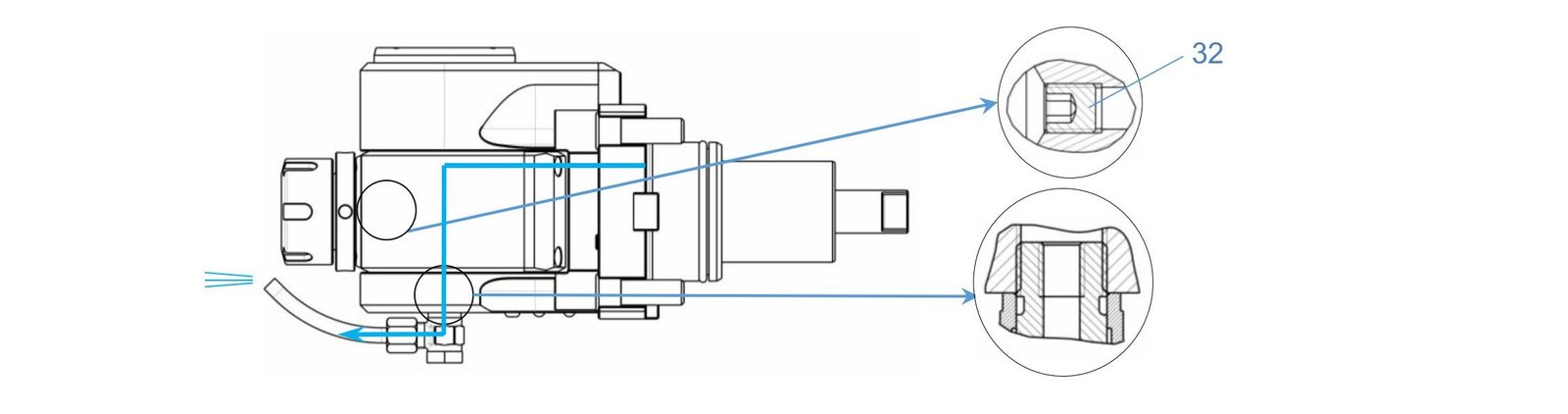

Internal cooling (BMT & VDI variable angle): The toolholders with internal cooling are prepared for this option

from factory. Toolholders provides coolant through the shaft, respectively by the cutting tool. For the internal

cooling of the cutting tool, remove the plug (32) with a hexagon Allen key and put in place plug (31) removing

the pipe assembly (15).

External cooling (BMT & VDI variable angle): Toolholders provides coolant through pipes. For external

cooling you have to: insert the plug (32) using a hexagonal Allen key, remove plug (31) and adjust the

orientation of the external cooling fluid from 90 degree fitting and the pipe.

2. PROBLEMS IN OPERATION

If a malfunction may appear during operation, lathe operator must stop immediately the using of the toolholder and customer needs to send a Service Request Document, if a such fault (failure) has been detected.

If there are problems or malfunctions with the toolholder, please contact the manufacturer / seller to return product for inspection, along with the service document.

Service Document, is stated at last page of present Instructions.

2.1 Instructions for products returning:

In order to keep the shortest repair times, please:

- Notify in advance that the product will be returned and propose a delivery date so that the repair can be scheduled in the internal service program. Products received without a service document will have a lower priority

- Provide product with a detailed description of the occurred problem, including as much information as possible.

- Without a service document, service department will not be able to repair the product on time.

2.2. Goods returned because of incorrect order, issued by the customer

In the event of a wrong order issued by the customer, the return of the product must be approved by the manufacturer / seller in advance. If approved, manufacturer will agree with the customer the replacement of toolholder. All transport costs will be bear by customer, in this case.

3. WARRANTY

- Defects that occur within 12 months from delivery date will be covered by producer warranty.

- The warranty does not cover damages or defects resulting from the negligence or improper use by the buyer personnel or if the products or their parts have been modified or repaired without the manufacturer's authorization.

- Repairs during the warranty period must be performed by the manufacturer or by a company / person approved by the manufacturer.

- The warranty is void if the product has previously been disassembled / repaired by unauthorized personnel.

- If repair is considered in warranty condition, this includes replacing of components that are subject to wear due to their intrinsic characteristics. However, the normal wear of these components cannot be considered as the sole reason for confirming the warranty.

- The seller or manufacturer will not be responsible for defects in materials or projects provided by the buyer.

- In particular, the manufacturer will not be held responsible for defects caused during transport and storage, misuse of the product by the customer (collisions), use outside normal working conditions, failure to observe the operating instructions and maintenance rules prescribed by producer.

- Repairs during the warranty period are made on the basis of a written complaint sent by the buyer, which must include a detailed description of the defect and which can be verified by the producer.

Repairs outside the warranty

For toolholders that are no longer covered by warranty, a standard toll charge of 60 EUR / toolholder, will be applied for disassemble and evaluation of the product state. If the Repair Offer is accepted by the customer and a Repair Order is received, this fee will not be paid by customer.

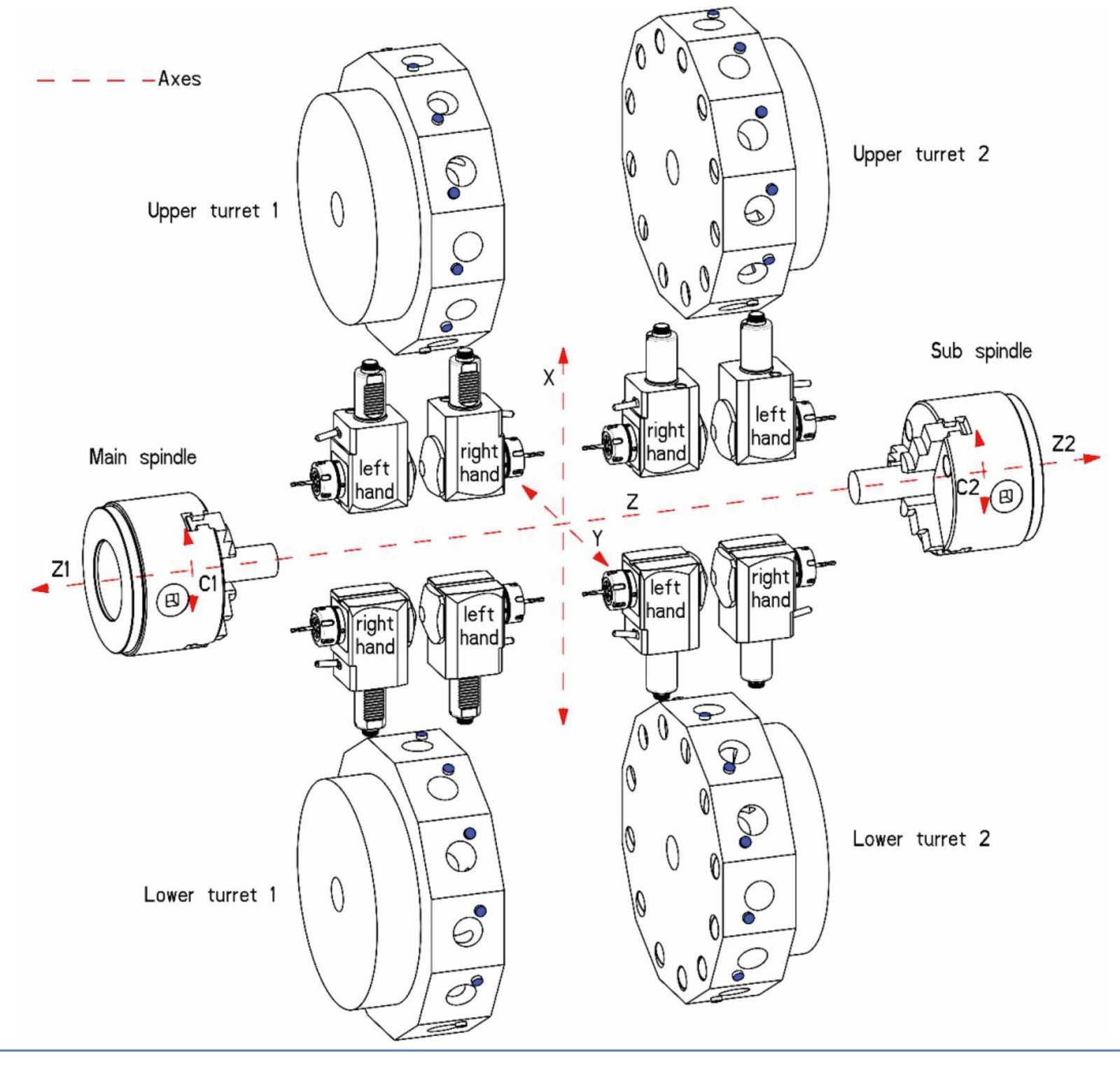

Operations with VDI Disk-type turret

Operations with VDI Star-type turret

1) When Will My Order Arrive At My Doorstep After Purchasing On ToolsEngg?

Shipping Of Goods From Our End Can Take Anywhere From 1 - 4 Weeks From The Date Of Purchase Order On Toolsengg.com. Most of the items listed on toolsengg.com are in stock so you can buy without any hassle.

2) Do You Provide Cash On Delivery (COD) For The Orders Placed?

No, At The Moment We Do Not Provide Cash On Delivery (COD) Option For Our Customers.

3) What Are The Various Payment Options Available For Purchase On ToolsEngg?

PayPal is the only form of Online Payment in USD we accept for all customers outside India, you can send us a mail to infotoolsengg@gmail.com if you intend to make a bank transfer to share Proforma Invoice with Bank Details for the same.

For Indian Customers you can pay through our secure RazorPay Payment Gateway in INR, you can send us a mail to infotoolsengg@gmail.com if you intend to make a bank transfer to share Proforma Invoice with Bank Details for the same.

4) How Do I Pay With PayPal?

Just Checkout on your ToolsEngg Shopping Cart and PayPal will be the default mode of payment for Checkout if your Shipping/Billing address is outside India.

5) What Is TE 100% Purchase Protection?

.png)

At ToolsEngg.com, we believe that customer satisfaction is key- therefore we stand behind all products bought by you at our website. We will replace any order within 7 days of delivery, with free return shipping if you receive a product which is not as per the specifications ordered by you

- Wrong Specification (than what was ordered),

- Wrong Type of Product,

- Wrong Quantity,

- Missing Parts/Accessories,

- Defective,

- Dead On Arrival,

- Damaged

However do make sure that the product has not been used or altered/tampered with, as well as is accompanied by its original price tag

and packing slip. Please contact our customer support at infotoolsengg@gmail.com, so we can help facilitate your return, At times we may also require additional verifications or information before accepting any return order. We will contact you if all or any portion of your order

is cancelled or if additional information is required to accept your order. If your order is cancelled after your payment has been done, the charged

amount will be refunded to you as soon as we can if within 24 hrs. In case of pre-shipment delays, ToolsEngg also offers you choice to cancel an order prior to its shipment by contacting us at Customer Support.Our Band of Trust define who we are and we promise the best online shopping experience to our customers.

6) Does ToolsEngg Have Any App To Purchase Tools Online?

Download The Free ToolsEngg App On Google Playstore For Exicting Offers On The Go.

7) How Do I Return A Product And What Is ToolsEngg Return & Cancellation Policy?

An Order is Eligible for 100% Refund including the return shipping costs under the following condition :

All The Returns Are Eligible For 7 Days From The Time The Customer Recieved The Product That They Wish To Return, The Conditions When Returns Are Accepted Are Explained Down Below :-

· When a wrong item is sent instead of the ordered item if this is the case then Products/Items should be UNUSED.

· Products should be returned in their original packaging along with the original price tags, labels and invoices.

· It is advised that the return package should be strongly and adequately packaged so that there is no damage of goods in transit.

· Once the returned items is received and in the exact unused state without any damage 100% Refund along with the shipping charge will be immediately initiated

A Product can be cancelled before 24 Hrs or Before Dispatch of the goods (either partially or entirely) whichever is earlier will be taken into account.

When Cancelled the payment gateway fee of 5% will be deducted for initiating the refund from the Total Invoiced Amount. If Toolsengg.com endures any other fees due to the cancellation that also could be included.

A product under no Circumstances can be cancelled when it has been dispatched from our premises or after 24 Hrs.

For any further further queries you are free to contact us at infotoolsengg@gmail.com at anytime, we would gladly answer any of your queries in a timely manner.

Thanks for shopping at toolsengg.com, If you are not entirely satisfied with your purchase, we're here to help.

8) Where are the Toolings displayed on ToolsEngg.com Manufactured ?

ToolsEngg.com is headquartered in Chennai, INDIA. All items are Made In India

9) What Are The Various Ways To Contact Us?

Email Us :- infotoolsengg@gmail.com

Phone :- +91 9841816287

Live Chat :- The Bottom Right Corner Of Every Page On ToolsEngg (Leave Your Name & Email Id If Our Staff Aren't Available On Live Chat)

10) Can Corporates Purchase On ToolsEngg?

Yes!!! Mail Us Your Requirements To infotoolsengg@gmail.com

A formal quotation along with bank details for transfer will be provided.

11) Which Country Is ToolsEngg Based In?

We are based in India for the past 30+ years. We ship to 200+ countries around the world.

12) Will I Be Liable To Taxes While Purchasing On ToolsEngg If I'm Outside India?

NO! You will not be subjected to any taxes if the shipping/payment address is outside India from toolsengg.com but you maybe subjected to your country customs duties, Only Indian Customers will have to pay GST as per the product, category purchased.

13) I am a Machine Tool Dealer, I'd Like To Regularly Purchase Your Products, Will I Be Given Any Special Prices?

You will need to mail in your company details to infotoolsengg@gmail.com with the subject line "I am a dealer". Our staff will have a look at our regular requirement and will take a call on a case by case basis, but the entire process will be pretty straighforward.

14) What Is So Special About The Products That You Offer On ToolsEngg Than Other Sites And Local Suppliers Online ?

Simple!

1) Quality

2) Tool Life

3) Cost

4) Customer Support

15) I Have A Drawing For A Tool (Collet, Solid Carbide Cutting Tool, PCD Cutting Tool) With Me Can You Manufacture For Regular Supply To us?

We do this in 2 ways,

1) If you have the precise drawing, send us the drawing to infotoolsengg@gmail.com to have a look at our dedicated page for this exact same requirement of yours

2) You give us a brief of the component that you need to manufacture and all the necessary details and send to our mail id infotoolsengg@gmail.com and we suggest you with a drawing, which can be a drill, holemill , reamer - we will work on the tool geometry and arrive at the best possible solution for your need and start supply once things are confirmed from both our ends.

16) Can I Sell On ToolsEngg.com?

You need to mail us to infotoolsengg@gmail.com for us to take a call on the product you offer.

17) Does Section 301 Tarrif apply on the goods purchased on ToolsEngg.com from the United States Of America

All goods purchased on ToolsEngg.com are manufactured and dispatched from India. Hence Section 301 Tarrif does not apply to any of the goods you purchase on ToolsEngg.com.

A brief explanation for what Section 301 is about :

Section 301 of the Trade Act of 1974 is a U.S. trade law that gives the President the authority to respond to unfair trade practices or policies of foreign countries. The law empowers the U.S. Trade Representative (USTR) to investigate and take action, which can include imposing tariffs or other trade restrictions, if it determines that a foreign country is violating trade agreements or engaging in practices that are unjustifiable and harm U.S. commerce.

The most prominent recent use of Section 301 tariffs was during the U.S.-China trade dispute, where the USTR imposed tariffs on a wide range of Chinese goods in response to practices like intellectual property theft and forced technology transfer. These tariffs have had significant implications for global trade, affecting businesses that rely on imported goods subject to these duties.

For more information visit the US Government website https://ustr.gov/issue-areas/enforcement/section-301-investigations/tariff-actions

Check if we are able to ship our products to your country

Worldwide Shipping Made Easy

Experience hassle-free shopping with our worldwide shipping services. Our shipping rates are automatically calculated based on the total weight of your shopping cart, ensuring transparency and convenience.

Have Questions? Reach Out to Us!

Feel free to drop us an email at infotoolsengg@gmail.com or message us on WhatsApp at +91 9841816287 for any queries or assistance.

Secure Packaging, Seamless Delivery

Rest easy knowing that your order is in good hands. We prioritize safe packaging and ensure a seamless delivery process right to your doorstep.

.png)