Carbide inserts are small, removable cutting tips that are used in a variety of machining applications. They are typically made of tungsten carbide, a very hard and durable material that can withstand high cutting speeds and temperatures. Carbide inserts are used for a variety of operations, such as turning, milling, drilling, and boring, on a wide range of materials, including metals, plastics, and composites.

The benefits of using carbide inserts include:

High wear resistance: Carbide inserts can withstand high temperatures and maintain their sharpness, even when cutting hard materials.

High strength: Carbide inserts are very strong, which allows them to maintain their shape and resist breakage.

High precision: Carbide inserts can be manufactured with very tight tolerances, which allows for greater precision in cutting operations.

High speed cutting: Carbide inserts can withstand high cutting speeds, which allows for faster machining and increased productivity.

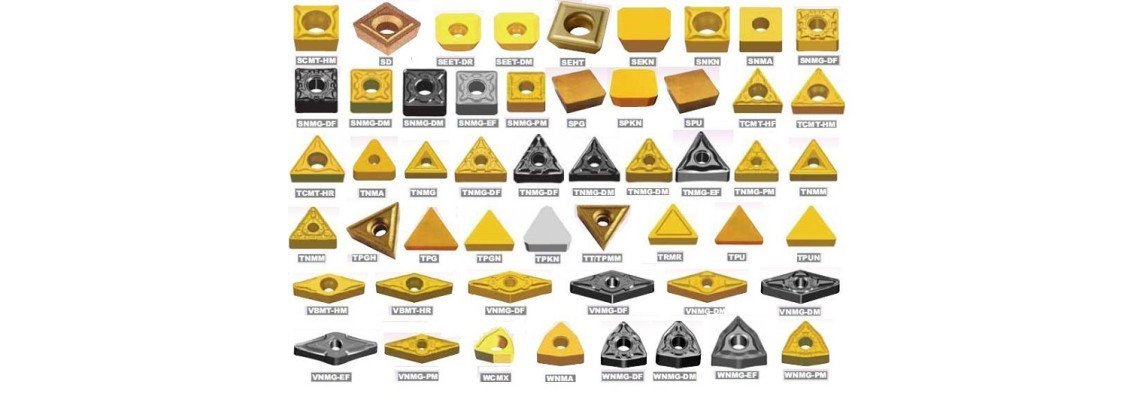

Versatility: Carbide inserts come in different shape, geometry and coatings to adapt to different type of materials and machining operations.

Cost-effective: Because of their long life and the ability to be resharpened or replaced, carbide inserts can save costs over time.

Leave a Comment